SIZE MATTERS

PROCESS

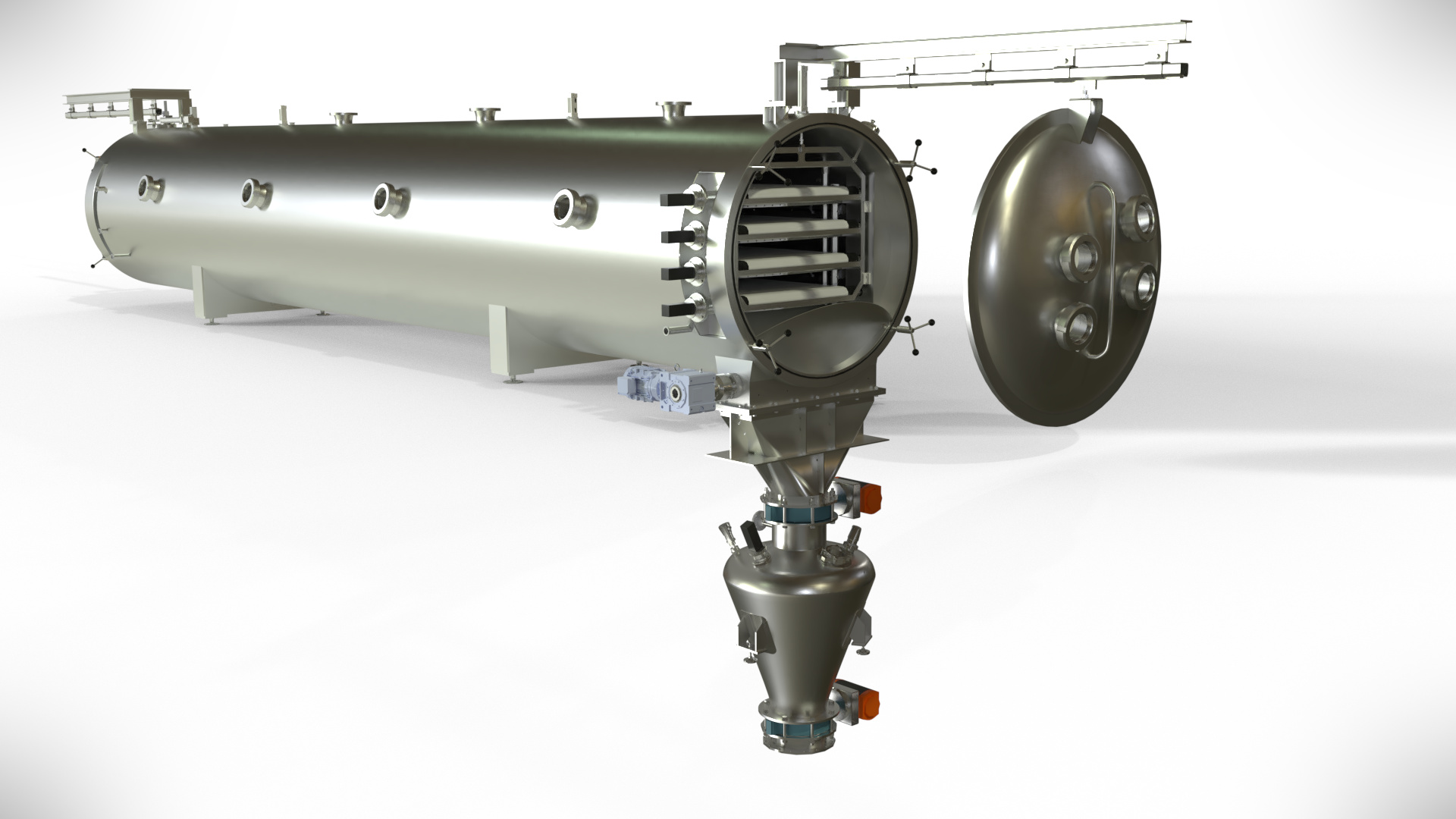

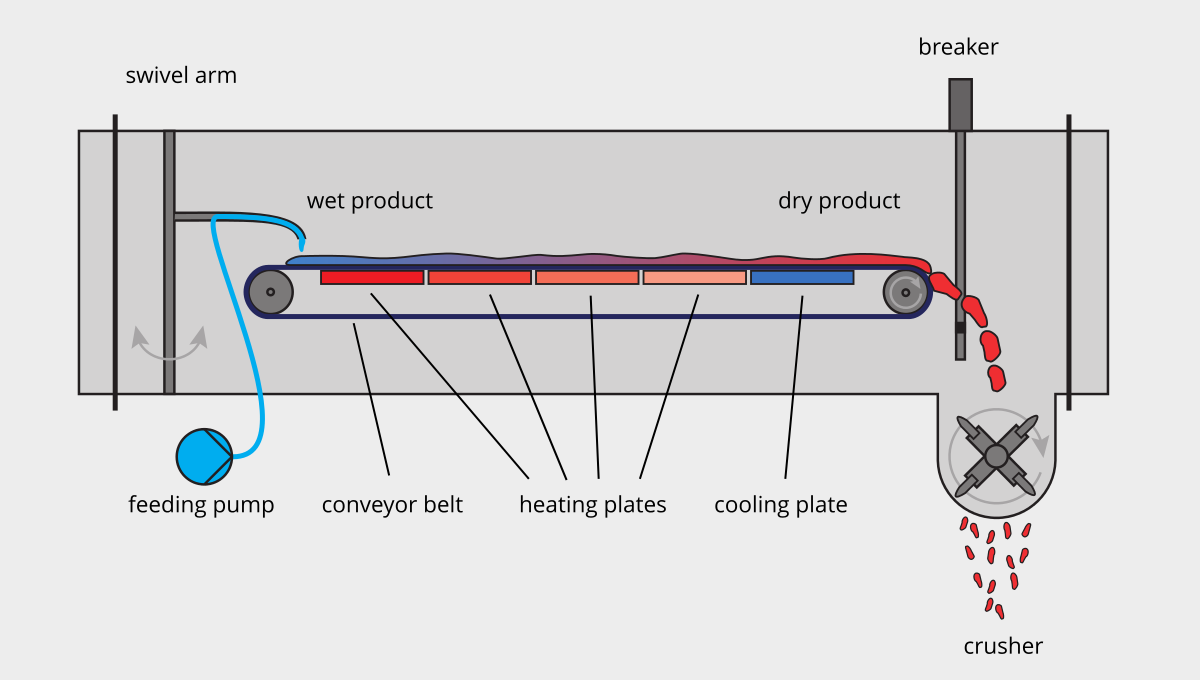

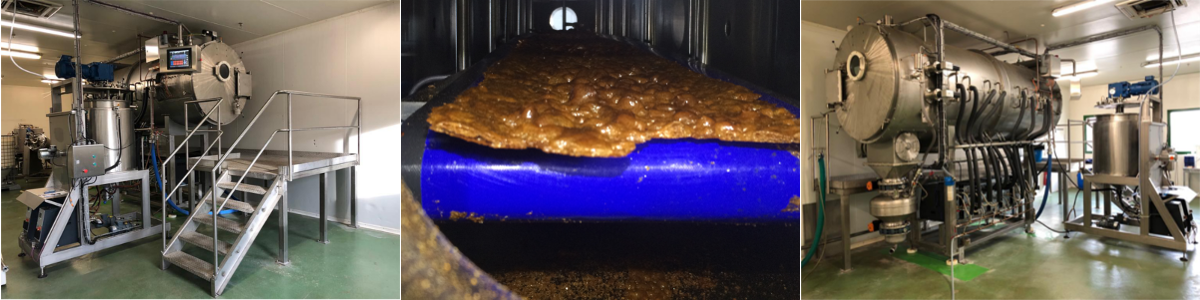

The process starts with mixing the liquid or pasty product in the hegatec Feeding Vessel. The feeding pump ensures a uniform distribution on the conveyor belt inside the dryer. The housing of the hegatec Vacuum Belt Dryer is under vacuum. The operating vacuum is precisely controlled by the hegatec Vacuum System. After feeding the product on parallel operating conveyor belts, it is conveyed through different heating zones and a final cooling zone. The integrated hegatec Inline Granulator mills the final product. The required dry matter of the final product can be regulated by adjustable parameters such as feeding volume, conveying velocity, temperature and pressure.

BENEFITS

- gentle drying by reducing the boiling point

- continuous, automated process

- fast drying

- low product temperature

- low loss of aroma

- no oxidation of the product

- controllable Maillard reaction

- very good water solubility of end products

- very good instant product properties

- possibility of solvent recovery

- automatic cleaning

INVESTMENT COSTS TO HIGH?

Think about a hegatec Retrofit of your existing dryer or an old one.

GENTLE DRYING

The benefit of vacuum drying is that water can be evaporated by low temperature because of the reduction of the boiling point. Vacuum drying is one of the most gentle drying processes. The hegatec Vacuum Belt Dryer is particularly suitable for:

malt and baking mixes · meat extracts · plant extracts · fruit concentrates and fruit pulps · vegetable concentrates · fruit pieces · vegetable pieces · aroma · baby food · chemical products · pharmaceutical products · and many more

QALITY STANDARD